Last year when my sister and I drove to Stampin’ Up’s convention in Salt Lake City we went quite a bit out of our way to stop in Kanab Utah, site of Stampin’ Up!’s manufacturing plant. It — was — interesting to say the least. The entire manufacturing plant visit was amazing.

I can’t figure out how to post a more direct link to Sara Douglass’s video of the process, so please click below to see how our stamp pads are made.

https://www.facebook.com/StampingWithBlythe/?hc_ref=PAGES_TIMELINE

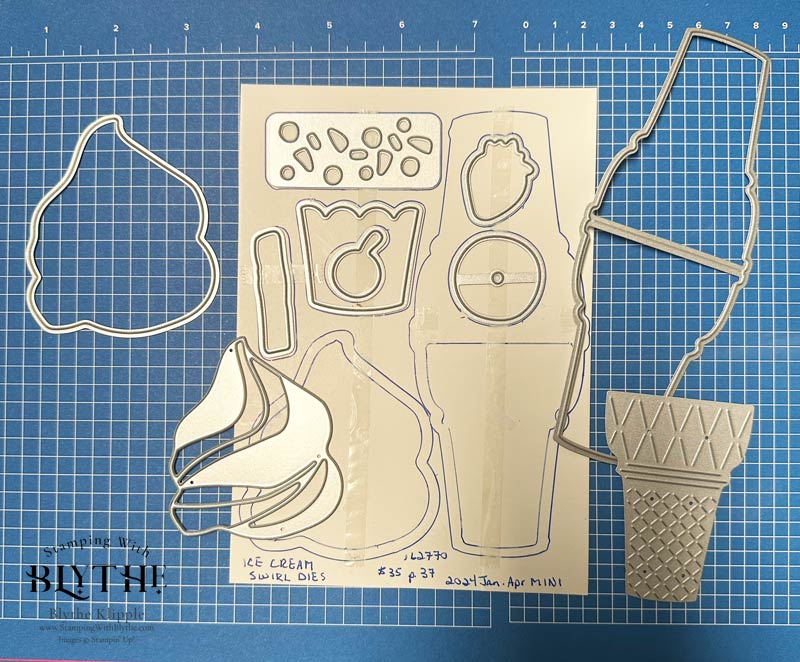

Once in a great while an over- or under-inked classic stamp pad will slip through the warehouse and into your order box. If that ever happens to you, let me know immediately! Stampin’ Up! will make it right immediately.

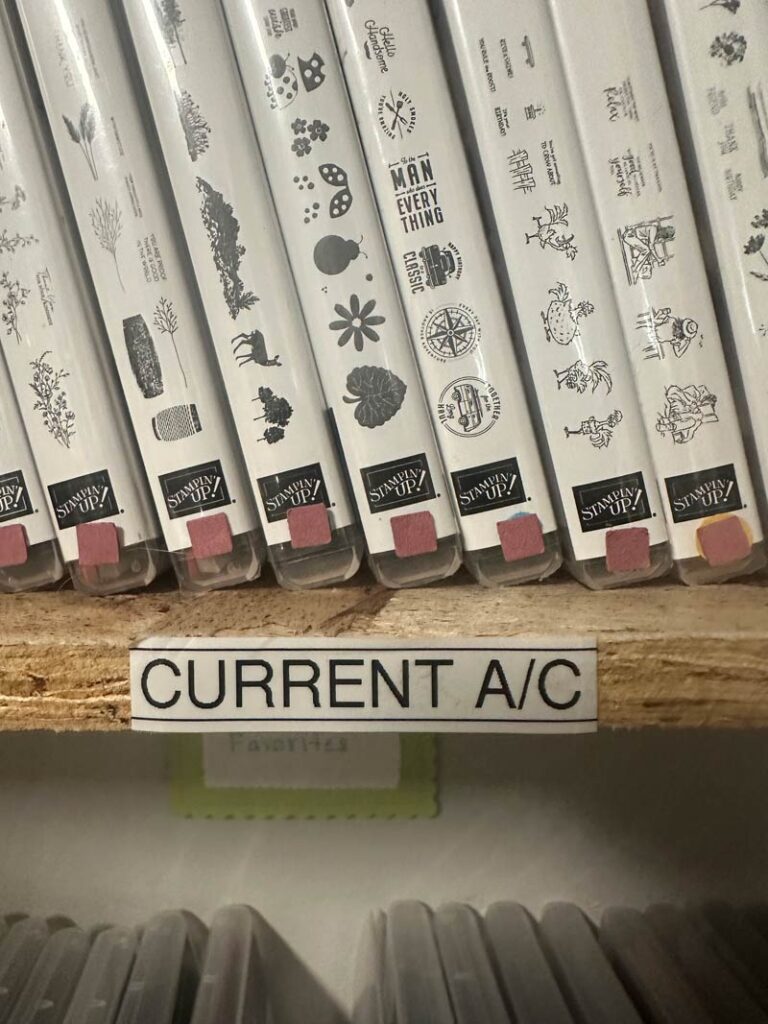

There is both manual and automatic labor from start to finish in preparing the stamp pads for us:

Be sure to check out the video for a much better view of the making of our stamp pads. You’ll have to scroll down a bit. I’m not always a technological genius! Enjoy it though.